Seal Design

Choosing the proper seal for an application can sometimes prove difficult. To help with this process we have provided an on-line form that will guide you through all the information needed in order to come up with a design for your particular application. As always, feel free to contact us directly and we can walk you through the design process.

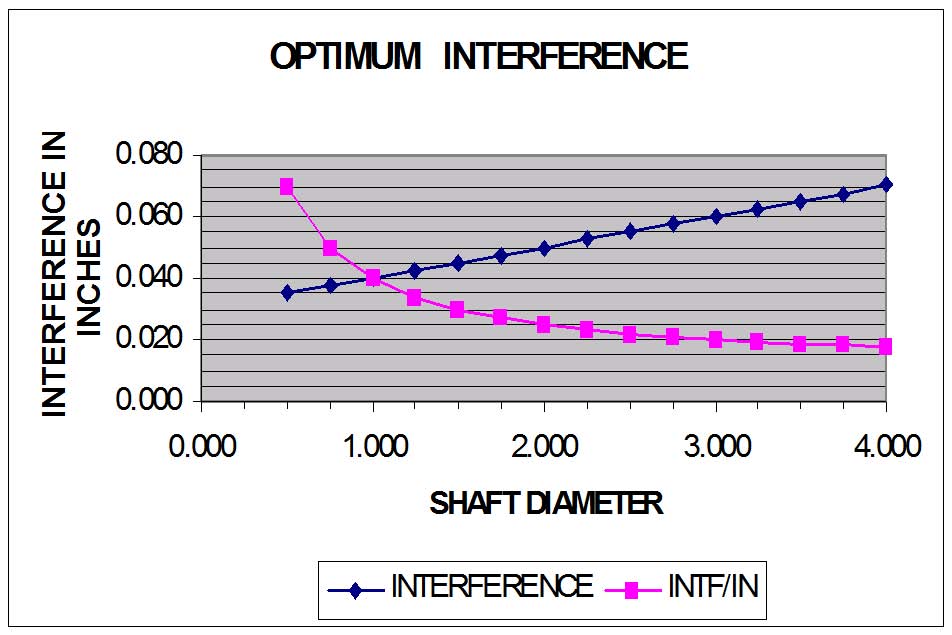

A question we get a lot is "What should be the proper interference between the shaft and the seal?". In days past, general industry seals were designed to cover a wide range of applications, and liberal tolerances on the shaft. Today most companies pay closer attention to their shaft tolerances and have tighter controls on their process, making it easier to get a more consistent shaft diameter. This said, assuming there is no significant shaft to bore misalignment or dynamic run-out, the graph below should be a good guideline for proper interference levels. Again, if you ever have any questions please don't hesitate to contact us.

Click here if you'd like a PDF version.

Login

News

February 23rd

Here is a great article on grease compatibility . . .

The Skinny on Grease Compatibility

July 30th

Here is a link to a great article about how to avoid particulate contamination . . . Obviously it goes without saying that a sealing...

How to Avoid Particulate Contamination