Sealing System Leakage Analysis - Case and O.D.

Measure Seal Outer Diameter

| Probable Causes | Actions or Countermeasures |

|---|---|

| Wrong seal for the application. | Check for proper seal identification. |

| Bore or housing reworked. | Check housing print. Also check for evidence of rework such as chuck marks. |

Check for Severe Scratches on the OD

| Probable Causes | Actions or Countermeasures |

|---|---|

| Damaged bore or bore chamfer. | Check condition of bore and chamfer. |

| Die scratches from case forming operation | Check for OD coating or sealant in scratches. |

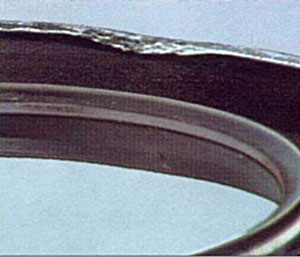

Below is an example of a seal that was installed with no lead in chamfer on the bore.

Check for Peeled Rubber on the OD

| Probable Causes | Actions or Countermeasures |

|---|---|

| Poor rubber bond to case. | Case OD clean at rubber interface. |

| Lack of lubrication of OD at assembly. | Case OD has rubber adhering to it. |

| Lack of proper lead-in chamfer. | Check bore chamfer condition |

Check for hardness on the Rubber OD

| Probable Causes | Actions or Countermeasures |

|---|---|

| Excessive heat in application. | Check for other evidence of overheating. |

| Improper seal material selection. | Check material vs. operating temperature or lube compatibility. |

Rubber OD Nonfills and Cuts

| Probable Causes | Actions or Countermeasures |

|---|---|

| Improper seal manufacture. Prep weight or shape out of spec. | Consult seal manufacturer. |

| Bore chamfer sharp or damaged. | Inspect bore chamfer. |

Go back to the top

Login

News

February 23rd

Here is a great article on grease compatibility . . .

The Skinny on Grease Compatibility

July 30th

Here is a link to a great article about how to avoid particulate contamination . . . Obviously it goes without saying that a sealing...

How to Avoid Particulate Contamination