Sealing System Leakage Analysis - Seal

Contaminants Packed in the Seal Area

| Probable Causes | Actions or Countermeasures |

|---|---|

| Failure of auxiliary lip | Look for cut or damaged auxiliary lip. Look for auxiliary lip worn excessively. |

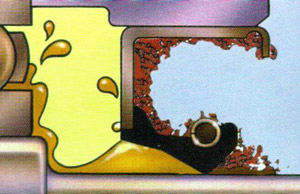

Below is an example of contamination cause by the failure of the auxiliary lip.

Paint Spray on Seal Lip

| Probable Causes | Actions or Countermeasures |

|---|---|

| Lack of paint mask. | Review painting procedures and recommend a mask. |

| Service or in-field paint procedure. | Issue a service bulletin to prevent paint over-spray or specify a mask. |

Check for Seal Cocking

| Probable Causes | Actions or Countermeasures |

|---|---|

| Seal installation. | Use proper installation tool. Check installation force to insure complete installation. |

| Insufficient or improper bore chamfer. | Provide proper amount and lead in angle for chamfer. |

| Excessive seal interference with rubber OD seal. | Check bore ID and seal OD for proper dimensions. |

Check for Proper Installation and Orientation Relative to Assembly

| Probable Causes | Actions or Countermeasures |

|---|---|

| Backward installation caused by lack of proper installation tool or visual aid. | Provide foolproof installation tool and/or aide to identify proper orientation. |

| Improper axial location of seal. | Provide proper installation tool. |

| Improper axial position of shaft. | Provide proper installation tool and visual aide for proper position |

Below is an illustration of a seal improperly installed backwards.

Check for OD Leakage

| Probable Causes | Actions or Countermeasures |

|---|---|

| Oversized bore/undersized seal. | Check bore and seal diameters at removal. |

| Damaged housing. | Check upon removal. |

| Damaged seal. | Check for OD damage upon removal. |

| Differential thermal expansion (Al or Mg housing). | Calculate fit at maximum temperature. |

Check for Case Deformation (Dishing or Damage)

| Probable Causes | Actions or Countermeasures |

|---|---|

| Dented heel face caused by hammer installation. | Provide proper installation tool. |

| Dished heel face caused by improper installation tool. | Provide proper installation tool. |

Below is an example of case damage most likely caused during installation.

Go back to the top

Login

News

February 23rd

Here is a great article on grease compatibility . . .

The Skinny on Grease Compatibility

July 30th

Here is a link to a great article about how to avoid particulate contamination . . . Obviously it goes without saying that a sealing...

How to Avoid Particulate Contamination